Punching and Sheet Cutting

Precise sheet punching and cutting – details that define perfection.

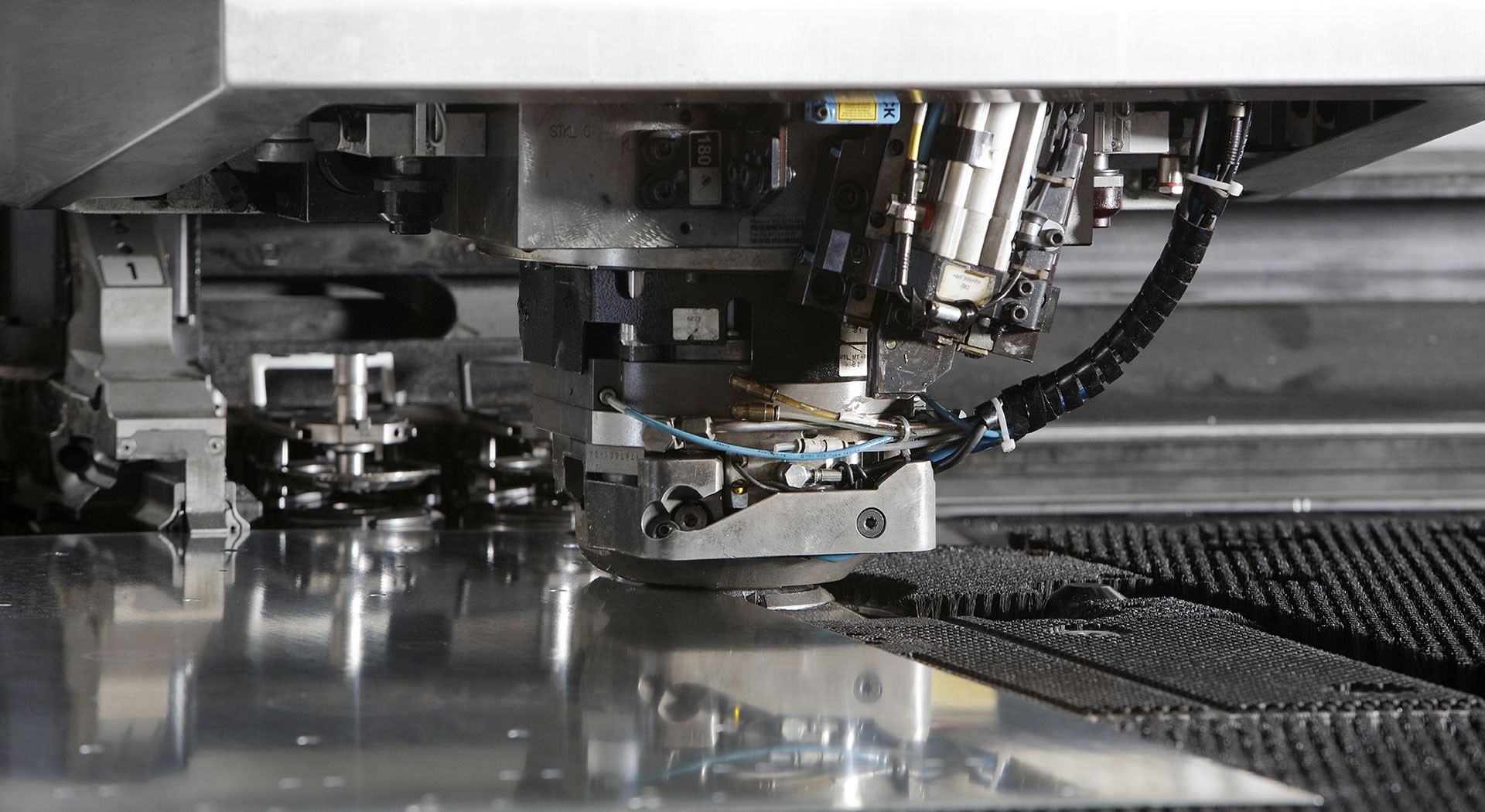

Punching is a manufacturing process that involves perforating metal materials to create specific designs, patterns, or holes with high precision. It uses punches to produce clean, detailed perforations, allowing us to offer functional possibilities across various industrial applications. At Gasori, we stand out for our ability to adapt to different designs and production needs by integrating the latest technological advancements.

We also offer several advantages through punching, including precision, speed, efficiency, cost-effectiveness, consistency, fast tool changeover, and minimal thermal impact, which help prevent deformation or alteration of the metal’s properties.

Advantages and Benefits

- Automated sheet loading/unloading and finished part extraction.

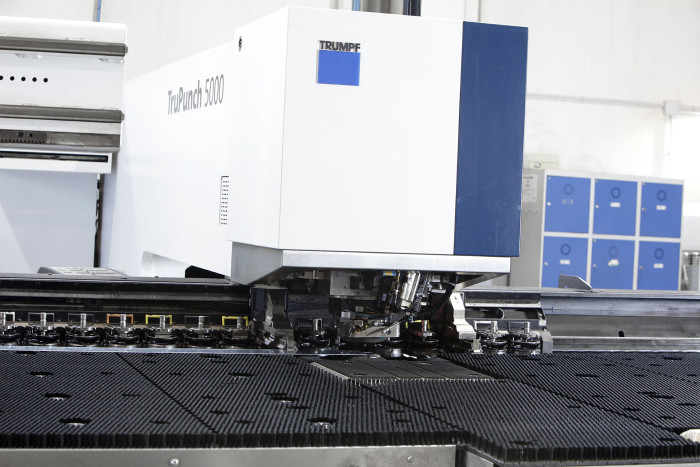

- Highly productive, state-of-the-art Trumpf machines: TruPunch 5000 and TruPunch 5000 with SheetMaster.

- Material waste is minimized thanks to the precision of the perforations.

- Various punching tools for standard shapes and special geometries, forming, deep-drawing, grilles, ribbing, countersinking, tabs, etc.

Technologies and Capabilities

Trumpf TruPunch 5000 Punching Machine

- Workingarea: 2500 x 1250 mm

- Sheet thickness: up to 8 mm

- Punching force: 220 kN

- Tools: 18 (3 clamps)

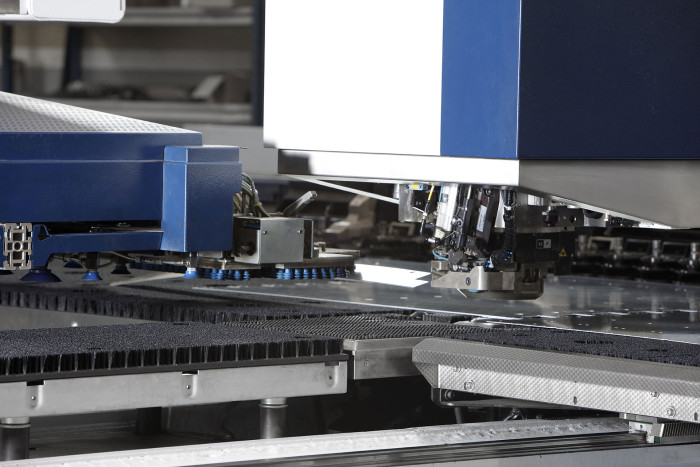

Trumpf TruPunch 5000 with SheetMaster

- Fully automated machine (loading and unloading)

- Format: 3000 x 1500 mm

- Sheet thickness: up to 8mm

- Punching force: 220 kN

- Tools: 18 (3 clamps)