Robotic Welding

Welding that goes further.

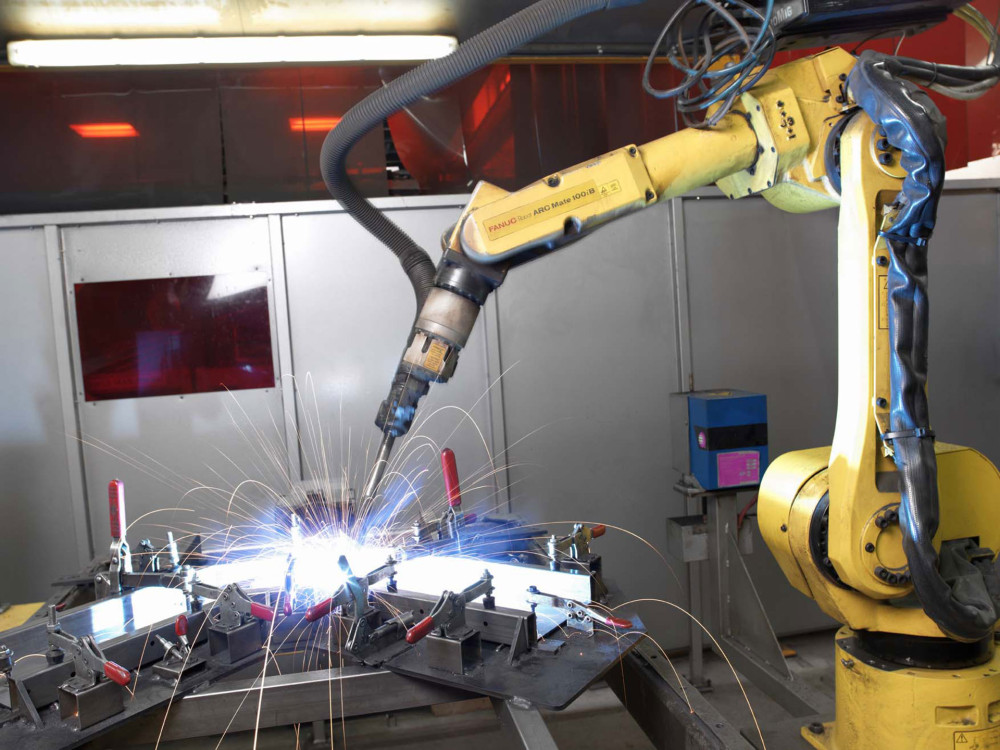

Robotic welding is an advanced manufacturing process in which automated robots join metal parts using an electric arc. This technique involves precisely programming robotic arms to control movement and arc application. At Gasori, we apply robotic welding across a wide range of industries thanks to its efficiency, speed, and ability to maintain consistently high levels of precision.

The benefits of robotic welding are clear regarding productivity and product quality. These automated systems deliver continuous output without fatigue, significantly increasing speed and efficiency compared to manual welding. This enables us to offer cost-effective solutions for large-scale projects and meet tight delivery deadlines. Moreover, robotic welding ensures exceptional consistency in every weld, reducing the margin of error and improving the structural integrity of the finished assemblies.

Advantages and Benefits

- We are equipped to carry out robotic welding processes for long and repetitive production runs.

- The robots are designed to optimize energy consumption.

Technologies and Capabilities

Robot

- Fanuc Arc Mate 100 iB

- Fanuc R-J3i Model B

- Specifications:

- Repeatability: ±0.008 mm

- Axes: 6

- Maximum reach: 1,885 mm

Robot

- Double table with Fanuc Arc Mate 100iC/7L robots

- CMT welding

- Specifications:

- Repeatability: ±0.1 mm

- Axes: 6

- Maximum reach: 1,882 mm