Sheet Metal Panel Bending

We precisely shape metal, creating industrial solutions that stand out in form and function.

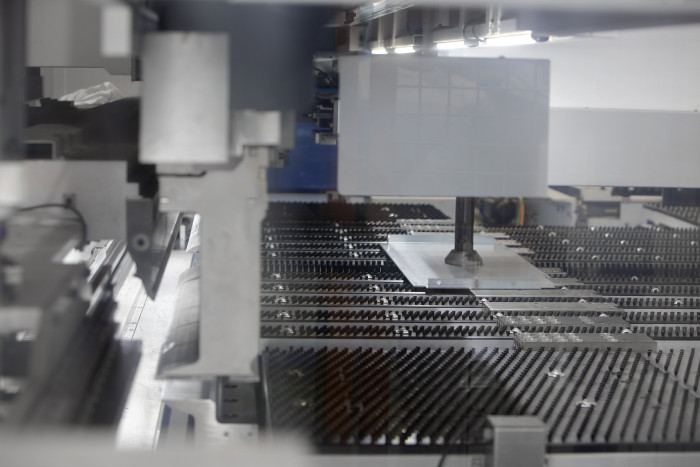

Sheet metal panel bending is a key process for accurately transforming flat metal sheets into three-dimensional components. At Gasori, we use advanced technology to carry out specific bends on tray-shaped parts, working with thicknesses of up to 3 mm in carbon steel and maximum lengths of 3,120 mm.

Our process enables positive and negative bends without flipping the sheet, optimizing production time and efficiency. In addition, we can produce bending radii through multi-bend sequences, meeting even the most demanding technical requirements.

The complete automation of the production cycle—from material loading to the unloading of the finished part—ensures smooth and efficient manufacturing. Precision is a cornerstone at Gasori: our machines are equipped with real-time angle correction systems, ensuring that every processed part meets the required tolerances.

This method is widely used in sectors such as metal furniture, electrical equipment, and storage systems, where quality and accuracy are essential.

Advantages and Benefits

- Advantages and Benefits TRUMPF panel bending technology with automatic loading and unloading, ensuring efficiency and precision at every stage.

- Ability to perform positive and negative bends and generate bending radii through multi-bend techniques without flipping the sheet.

- Integrated real-time angle correction system to ensure all parts are accurate.

- Adaptable to various industrial sectors, including metal furniture, electrical equipment, and storage solutions.

Technologies and Capabilities

Trumpf TruBend Center 7030 Panel Bender

- Maximum size: 3120 x 1500 mm

- Maximum thickness (carbon steel): 3 mm

- Maximum thickness (stainless steel): 2.2 mm

- Maximum thickness (aluminum): 4 mm

- Minimum material thickness: 0.5 mm